Find Tool Making Industry Diamond Roller, Diamond Dressing Roller, Tool Making Diamond Dressing Roller on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 20 Days |

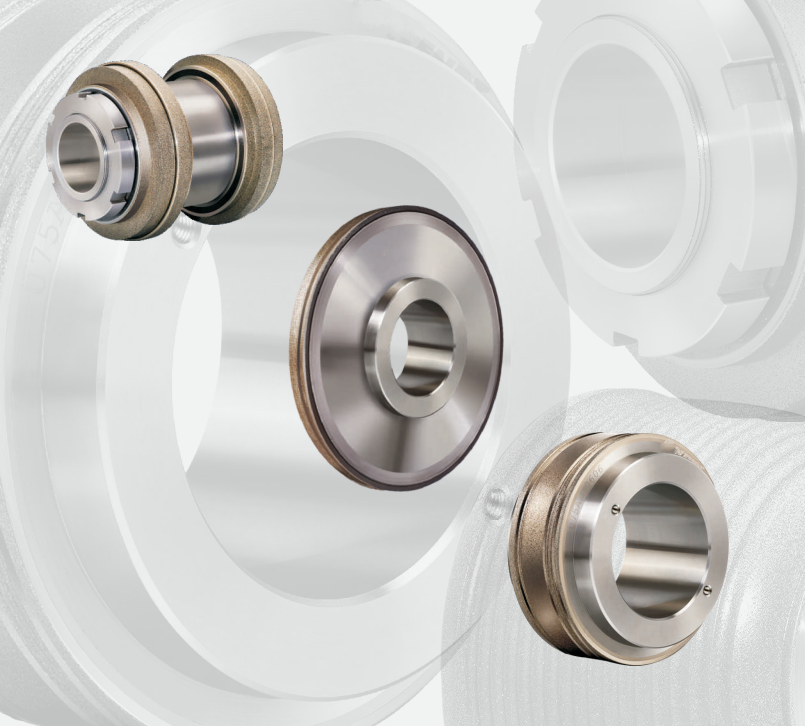

Tool making industry diamond dressing roller

Application:

Automotive Industry – Tool making industry :

Screw Taps, Thread Rolling Dies, Drill Bushes, Broaches,Clamping Jaws etc

Rotary diamond dresser

These dressers shape Grinding Wheel in the shortest possible time. Their features:

Profiling grinding wheel in one step through plunge grinding

Profiling from the simplest work piece to the most complicated shape

Meeting exacting precision demands

Offering high economic efficiency

Diamond form rolls

These form rolls shape Grinding Wheels in automatically controlled cnc dressing operations. Their features:

Profiling grinding wheels by moving the diamond form roll along the required contour

Profiling from the simplest work piece to the most complicated shape

Meeting exacting precision demands

Offering high economic efficiency

Diamond dressing blocks

These dressing blocks are ideal alternatives to rotary dressing wheels in application where mechanical dressing is considered non-economical. These can be mounted by using simple attachments to machines

Selection of dressing tools

Type NZ (Randomly distributed diamonds)

Type NS (hand set diamonds)

Type NM (hand set/Randomly distributed diamonds)

These tools are produced by reverse planting method

In this diamond grain is actively involved in the dressing action, leading to long service life. These type of rolls are used for intricate profiles & tighter tolerances NZ type dominates in application of almost all types of profiles, especially where surface finish is important. NM type is preferred where work pieces are prone to grind burn.

Type IZ (Randomly distributed diamonds)

Type IS (hand set diamonds)

These tools are produced by infiltration in the reverse method.

These types of tools can meet critical tolerance levels, IZ type tools, depending on the profile, ensure shorter manufacturing cycles. The IS type is particularly suitable for profiles with intricate links that can not be produced by reverse plated method. Both IZ and IS types are extremely robust in construction.

Type PM (Randomly distributed diamonds)

These tools are produced by direct plating

Due to random distribution of abrasive grits, the surface of the rotary dresser is relatively rough and uneven, these tools are therefor extremely aggressive and achieve rougher surface finish. Thus they are not suit for application that call for high accuracies. The body can be recoated more than once, contributing to economic efficiency of the tool, Also their manufacturing coast is relatively low.

Type SM (Diamond interspersed)

These types of tools are produced by sintering, using mixture of diamond and bond.

While the grit size equals the thickness of coating in all types of abrasive tools, only in this type it is possible to obtain thickness in multiples of the grit size. Thickness of 2, 3 and 5 mm are standard. Since this type of dressers cannot be produced to a high degree of accuracy, they are ideal for simple profiles.

Product Categories : Diamond Dressing Rolls